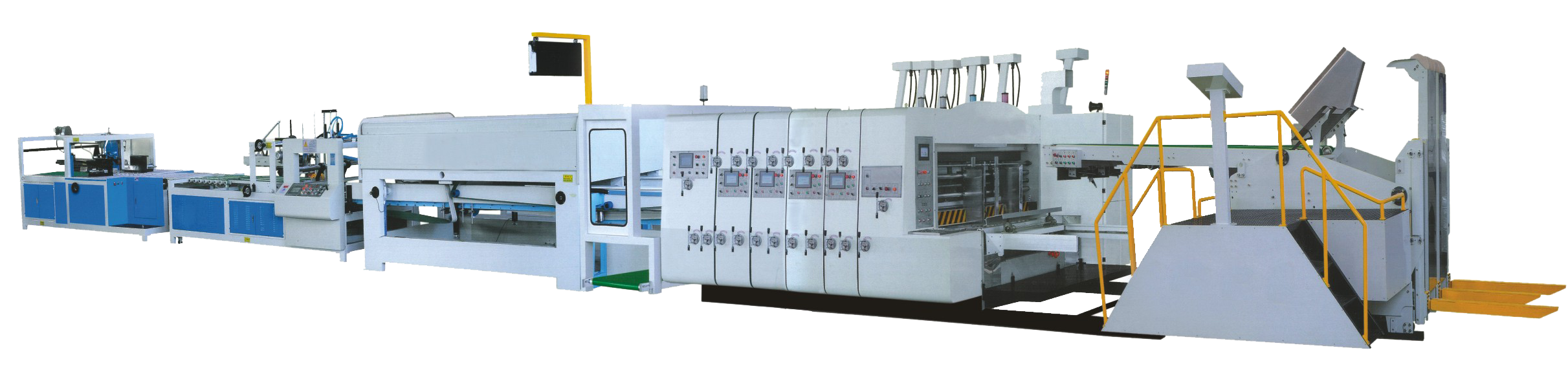

Lead Edge Printer Cum Folder Gluer With Online Bundler

Technical Features:

Our machines adopt advanced design technology, it realized the continuous and efficient production, it perfectly combines with print, gluing box, and bundling. So it successfully reduces labor intensity, and machine area. It extensively improves the production efficiently and user friendly operation. Our machine can produce easily 10000 cartons per hour.

Technical Specifications:

Designed According to the high request and the reliable function, the operation of the machine is humanization, can accomplish the setting, revision, implement, replacing and memories function in a short time, and display with a exact data.

All the drive rollers adopted high quality steel materials, hard chromium plating and the surface treated by laping finish.

The drive gears adopt high quality alloy steel 20CrMnti, after heat treatment and laping finish.

The main drive roller adopt keyless connect, decrease the connection gap, guarantee the printing precision.

Lubricte oil automatic balance device, keep the equal oil level equal in each unit.

The machine adopt PLC control, with “automatic zero return” and “memories” function (Can choose PLC with touch screen to control).

Mechanical edge-leading feed type (Can choose servo lead edge feeder type).

Can adjust wind to suit different size paper by frequency converter in feeding part.

Consum can chose steel anilox roller or cereamic roller, the lines of the anilox roller also can be chosed accord to the customer requirement.

| Model number | Unit | NXGN300-2100 | NXGN405-2300 |

|---|---|---|---|

| Roller diameter | Mm | 300 | 405 |

| Max. Feeding Size | Mm | 950X2300 | 1270X2500 |

| Max. Printing Area | Mm | 850X2100 | 1150X2300 |

| Max.skip Feeding Size | Mm | 1100X2300 | 1300X2500 |

| Min. Feeding Size | Mm | 260X650 | 350X650 |

| Thickness of cardboard | Mm | 2-11 | 2-11 |

| Standard thickness of printing plate | Mm | 7.2 | 7.2 |

| Printing Plate | |||

|---|---|---|---|

| Max.machinery speed | Pcs/mm | 200 | 180 |

| Economic printing speed | Pcs/mm | 150 | 150 |