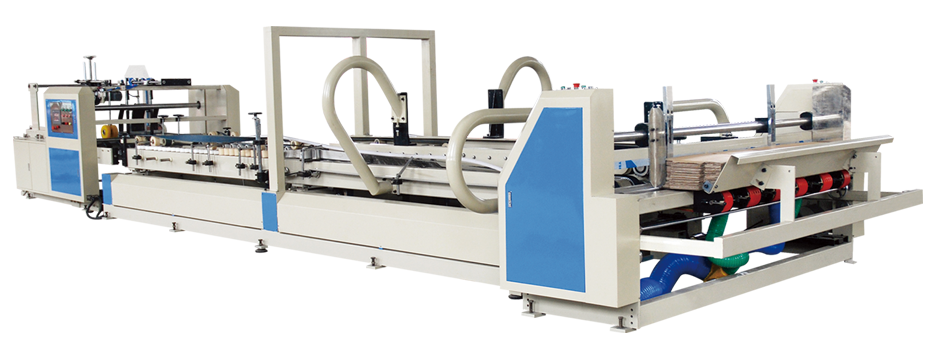

Automatic Folder Gluer

Description & Feature:

1.QF-AFG series automatic folder gluer machine consists of three sections: vacuum feeding section, gluing and folding section, counter and stacker section.

2.All motors except frequency conversion motor adopt Taiwan shengbond motor,. Frequency conversion motor, with quality inverter adjusts speed. PLC and Touch screen control system for easy operation and running stable. The maximum speed is 130meters/min, average speed is 100meters/min. Energy conservation and high speed, saving labor cost.

Feed Part:

1.Vacuum suction feeding to feed warping paperboard easily.

2.Adopt high-quality electromagnetic clutch and brake system, Feeding part independently control, easy operation, reliable performance.

3.Adjustable Scorer wheel, suitable for 2-8 mm thickness paperboard Second creasing structure, can creasing again for the paperboard that didn’t creasing well.

Glue Folding Part:

1.Simply structure and high reliability, glue quantity adjustable, clear easily.

2.Adopt stainless steel glue wheel, make glue uniformity, long working life, save glue quantity.

3.Adopt imported antiwear rubber conveying belt, Automatic folding.

4.Equipped with paperboard calibration device & creasing calibration device.

Counter and Stack Part:

1.Stacker and counter are simple and reliable.

2.Digital control, operation easily and reliable. No stop machine when input data, Automatic counting and accurately output.

3.With rectify deviation function, adjustable deviation.

4.Counting and output adopt pneumatic control, steadily and quickly.

Technical Parameter:

| Model | QF-AFG 2400 |

|---|---|

| Max.Cardboard | 1200X2400 |

| Min.Cardboard | 300X900 |

| Dimensions | L12500XW3200XH1600 |

| Total weight | 6000KW |

| Power required | 12KW 415V 3 phase 50HZ |

| Paperboard thickness | 3 or 5 layer paperboard |

| Control | PLC&TOUCH SCREEN |

Automatic folder gluer electric control parts introduction

1.Main electric refer to European standards, Design and production concept is working safety and operation conveniently. Adopt colorful touch screen and Panasonic PLC control, operation easily. Touch screen and main control PLC all have application upgraded interfaces, for the program upgrade in the future.

2.The machine main motor adopts frequency conversion motor with quality inverter adjust speed, using HLP inverter, speed steady and saving labor cost( save 30% electricity cost), meanwhile protect the motor.( when the voltage is too high or low, the motor is too hot or the excessive current, the inventor can alarm automatically and stop running, then The corresponding code will appear).