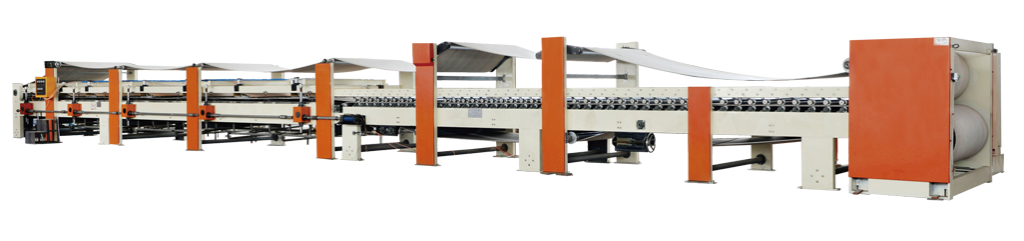

Structure features:

1.Whole rack adopt high-strength 30 # or 40 # channel steel,tough structure and work steadily, Glue rollerΦ270mm; cardboard thickness:130mmSurface is grinded and plated chrome.Electric adjust glue space.PLC control and touching press stick

2.Hot plate 17 pieces,heating plate with high strength container board production, accords with national safety standards for pressure vessels. 600mm wide steel hot plate , inside S -shaped guide airflow structure , improve the utilization of steam . Many remain hot plate welded stiffeners never deformed . Pressure vessel with a certificate and inspection certificate .

3.Heating zone structure using intensive pressure roller or hot plate structure,cardboard stereotypes firm adhesion formation .

4.Steam pipe inlet,exhaust port by the S -shaped arrangement , hot plate temperature equilibrium and even.

5.Hot plate temperature control separately, height adjustment to adapt to the speed . ( Or optional temperature * Digital display )

6. Heating section with electric or hydraulic roller weight overall increase , smooth movements , safe and reliable.

7. If you choose electric hoist big band,with a horizontal cycloid motor 2.2kw;

If you choose a large hydraulic lifting belts, hydraulic station is 4.0kw.

8.Upper conveyor belt with automatic,manual correction device each 1set,

tension pneumatic, manual adjustment each 1set;Lower conveyor belt with tension and corrective device adjustment.

9.Large diameter drive unit with a textured high- abrasion rubber,lower conveyor belt slippage and to prevent belt deviation;Improve the stability of operation of the device to ensure that the output level of cardboard .

10.Separate gear box drive,low noise,using oil immersion sealed gear;Optional electromagnetic speed motor or inverter motor drive .

Technical Parameters:

| No |

Name |

Technical parameters |

|---|

| 1 |

Effective working width |

1800mm |

| 2 |

Operation direction |

According to the customer require |

| 3 |

Steam practive |

1.2-1.8MPa |

| 4 |

Compressed air |

0.6-1.0Mpa |

| 5 |

Steam temperature.compress |

160-200°、0.9-1.3MPa |

| 6 |

Electric lift belt motor |

Horizontal cycloid motor 2.2kw(choose) |

| 7 |

Hydraulic lift belt motor |

Hydraulic station 4.0kw(choose) |