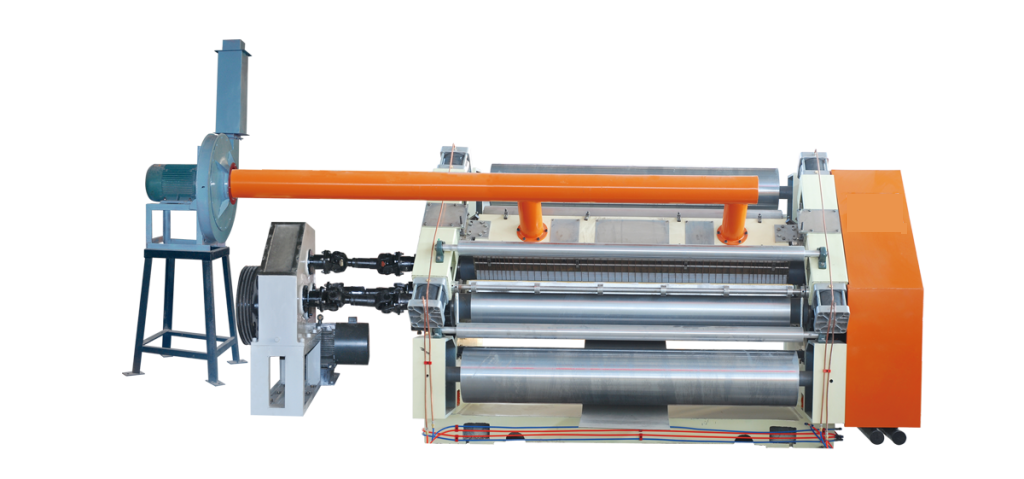

NXGN-B 280 Adsorption type single facer

1.Adopt vacuum adsorption method paper feeding with high-pressure powerful air blower. Equipped with air conditioning machine air suction device; and censored The electrical control focused on the same electric ark distance not less than 1.5 meters, host operating side closed side cover.

2.Gimbal transmission can be chosen, the body structure independent driver box. Enclosed gear transmission oil lubrication, can prolong the service life of gear.(option)

3.Glue-coating roller and fixed rubber roller design for group guide sliding, disassembling conveniently.

4.Base and wallboard cast iron structure, wallboard thickness for 200mm.

5.Corrugated roller adopts 48CrMo high quality alloy steel, via piece.modified, quenching, surface polishing, corrugated roller diameter Ø280mm, surface hardness for HRC58-60 degrees,

6.Corrugated roller adopt cylinder controlled fluctuation displacement.

Pressure roller diameter Ø 280mm, surface treatment processing and kill chromium plating, Cylinder controlled fluctuation, material for medium-carbon steel displacement 45, modulation handle.

7.Corrugated roller and pressure roller bearings use high-temperature grease lubricated bearing.

8.Pneumatic control to glue back glue, glue roller diameter Ø 240mm, surface polishing after engraved with hard chromium plating pit type anilox roll surface treatment, adjustable glue hard chromium plating kill processing and handling.

9.Corrugated roller unilateral high 0.10 mm, pressure roller unilateral 0.075 mm high. Add pneumatic device, pressure cylinder for Ø 1.6 mm cylinder

Technical parameters:

Work width:1800mm

Design speed: 180 meters per minute.

Operation direction: left or right hand (need according to customer’s plant sure).

Source: 0.4-0.9 Mpa.

Steam pressure: 0.8-1.3 Mpa.

UV corrugated flute type

Roller class diameter parameters:

Corrugated roller diameter Ø280 mm.

Pressure roller diameter: Ø 280 mm.

Glue-coating roller diameter: Ø 240 mm.

Preheat roller diameter: Ø 400 mm

Dynamic motor parameters:

The main motor: 15KW 440V 50HZ

Air suction motor: 15KW 440V 50HZ